Weigh Tank Configuration Options

An overview of configuration options for weigh tanks.

Applies to

- Weigh tanks / KA-2000PS running as 2300.

Usage

A weigh tank is a large cone-bottom tank set on a platform scale or load cells and serves the function of measuring out multiple products and dispensing them.

Weigh tanks function in two stages: fill and discharge. As with all Kahler Automation products, weigh tanks are highly configurable. These configurations can be divided into three sections: panel settings, discharge settings, and KA-2000 settings.

Note: Fill limits can also be applied to weigh tanks. More information can be found on the article on Fill Limits.

Panel settings

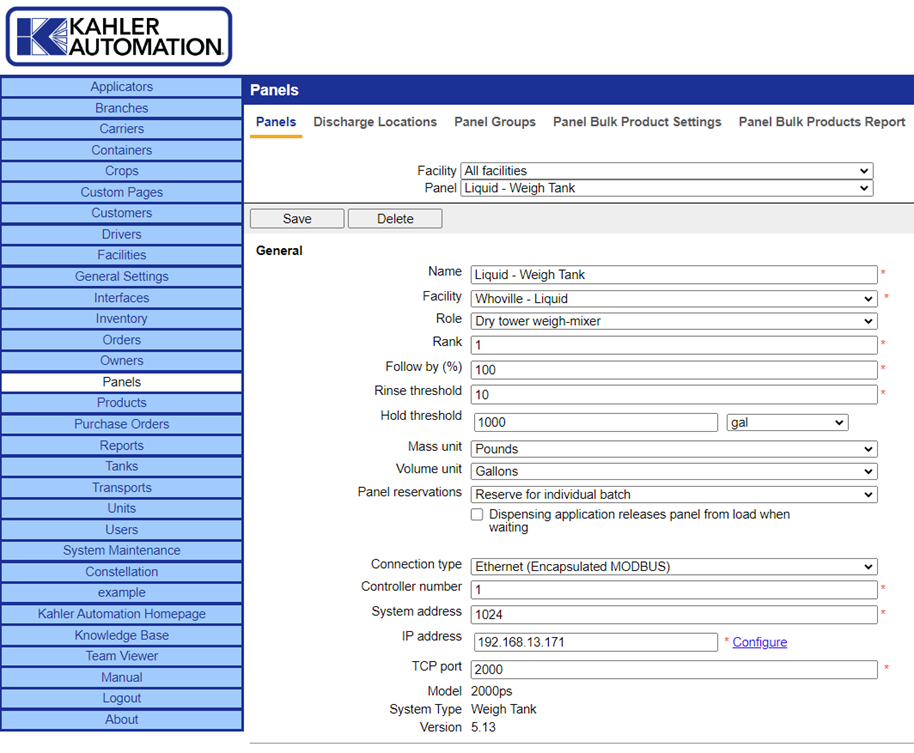

Weigh tank panel settings are found in the Panels section of Terminal Management TMX, under the Panels tab. While most of these settings are set during site commissioning and should not be modified by end users, there are two settings of note on this page: Follow by (%) and Rinse threshold.

Follow by (%) determines when the weigh tank can start discharging based on the controller ranked lower than the weigh tank, normally a carrier line. 100% means that the weigh tank should wait for the controller before it finishes, while 10% would mean that the other controller has dispensed 10% of its total amount ordered when the weigh tank starts dispensing. A common starting point for weigh tanks is 10%.

The Rinse threshold turns on the tank rinse function during the discharge operation. This setting will always be based on the scale unit of the weigh tank, and once the scale reads below the configured amount will remain on until dispensing is finished. If more rinsing is required, raise the rinse threshold; if less rinse is required, lower the rinse threshold.

Discharge settings

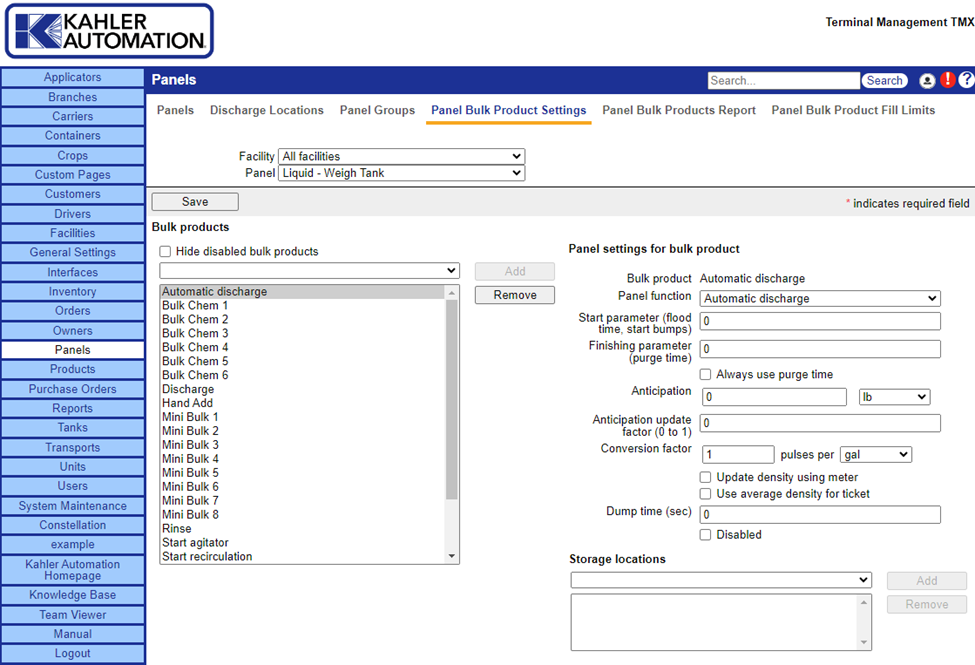

Found in the Panel Bulk Product Settings tab under Panels, weigh tanks will have two discharge panel functions: Automatic Discharge and Discharge. These panel functions use the start and finishing parameters of the panel bulk product setting to control the pump flood time and purge time respectively, and should match between automatic discharge and discharge.

The Start parameter sets how long to flood the pump before it is started. This prevents cavitation and air lock issues.

The Finishing parameter sets how long an air purge is needed once the weigh tank is empty, to purge the line.

Note: These discharge settings are specific to the discharge stage of a weigh tank and are unrelated to the particular products in the weigh tank.

KA-2000 settings

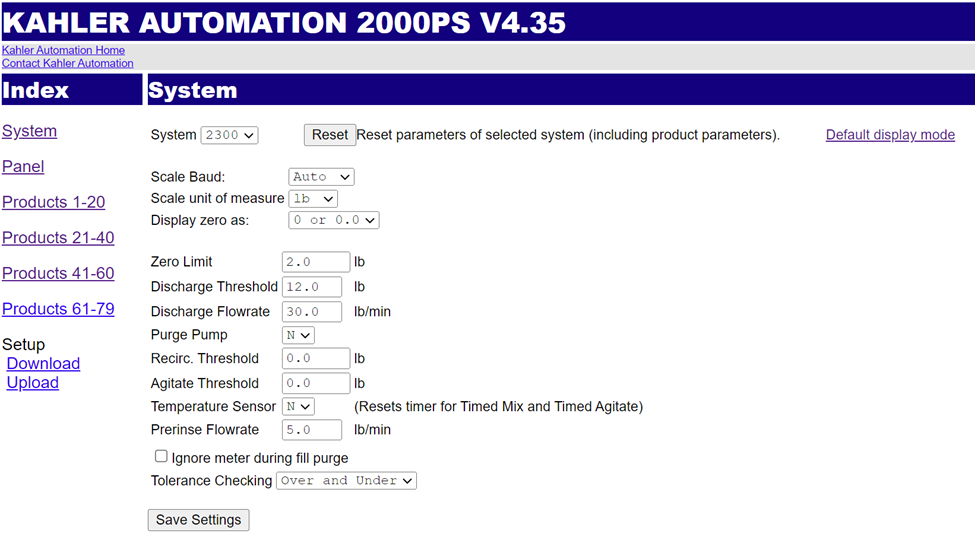

While many weigh tank settings are set in Terminal Management TMX, some are set in the KA-2000 that controls the weigh tank. To access these KA-2000 settings, start at the Terminal Management TMX Panels tab, as shown in this document’s first screenshot above; click the “Configure” link next to the “IP Address” setting. This will open a new webpage for the KA-2000 configuration menu. Click the “System” link on the left-hand side of the screen. If asked for a username and password, enter the password of “6648” and no username.

Note: Your network connection must be local to the KA-2000 to reach the system. Some network configurations may only allow select computers to access the KA-2000.

The System page should look something like the screenshot above. The settings at the very top of the page (System, Scale Baud, Scale unit of measure, and Display zero as) are determined at commissioning and should not be modified. Modification of these settings may result in the system being inoperative.

The other settings are described in the table below.

|

Div. Mode |

Hold: Holds last diverter setting when done discharging. |

|

Zero Limit |

Weight on scale below this amount is treated as empty, otherwise operator will be given a “weight on scale” error. |

|

Discharge Threshold |

During discharge, the scale falling below this mark triggers a countdown to turn off pump. |

|

Discharge Flowrate |

During discharge if the change on scale is below this amount, a “no weight change” error will be given to the operator. |

|

Purge Pump |

Y to run pump during purge, N to turn pump off before purge. |

|

Recirc. Threshold |

Determines when the recirculation function can start. |

|

Agitate Threshold |

Determines when the agitation function can start. |

|

Temperature Sensor |

If a temperature sensor is equipped, and this setting is set to Y, the timed mix timer will not run until the temperature sensor reports a 0 signal. |

|

Prerinse Flowrate |

The minimum flowrate for the Prerinse. If the flowrate is below this minimum amount, a "low flow" error is reported. |

|

Ignore meter during fill purge |

When enabled (checked), the product added to the scale during purge will NOT be recorded as delivered on the order. |

|

Tolerance Checking |

Under: Only warn if under-delivering (i.e., the over tolerance limit warning is disabled). Over and under: Warn if under- or over-delivering a product.

|

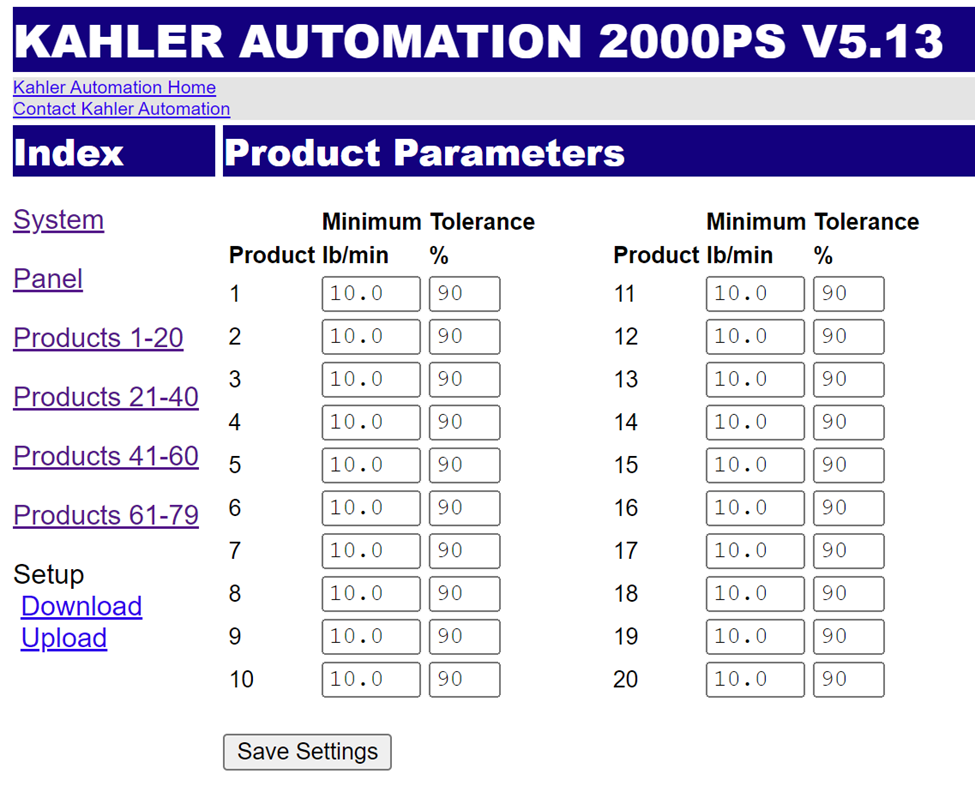

Tolerance is set per product function in the KA-2000 -- see products links on left side of screen (“Products 1-20”, etc ) -- and is a percentage of the order amount.

Under tolerance is defined as:

- less then (order amount * Tolerance percent)

Over tolerance is defined as:

- greater then (order amount * Tolerance percent) + (order amount)

Further reading

“Do Not Stack” configuration in Plant Supervisor PSX

Still Need Help?

Submit an online web ticket or call us at Kahler Automation 507-235-6648 Option 2.