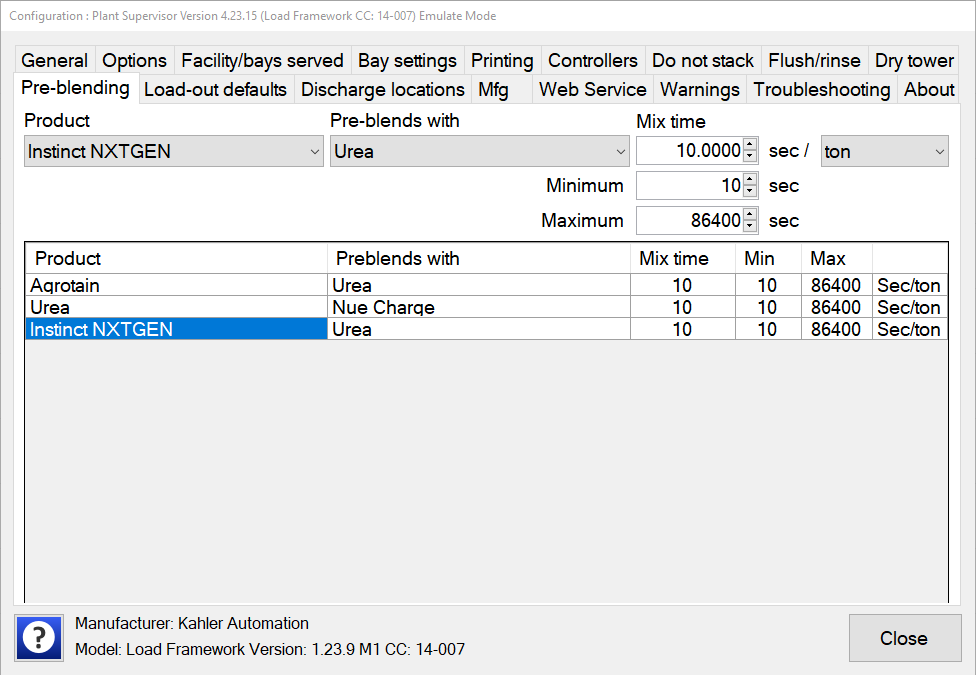

“Pre-blending” configuration tab in Plant Supervisor PSX

Configuring Pre-blending allows for a dry tower to automate coating operations on specified products, separate from the rest of an order.

Applies to

- Dry systems needing to pre-blend products to apply a coating automatically using Plant Supervisor PSX

Usage

Pre-blending allows specifying a pair of products and setting a pre-blend mix time for the pair. When the pair of products is found together in an order, they will be loaded to a mixer first, the pre-blend mix cycle will run, and then the remaining products, if any, will be added and mixed.

- From the configuration tab of Plant Supervisor PSX, click the “Pre-blending” settings tab.

- Select the first product from the “Product” dropdown.

- Select the second product from the “Pre-blends with” dropdown.

Note: When using Pre-blending each blend can only start with a product 1 time, but the same product can be used in other Pre-blends if it is set in the "Preblends with" column.

- Set the mix time by setting how many seconds to run per unit of measure (lbs., ton).

- Set a minimum and maximum mix time.

TIP: Setting the mix time per unit of measure to zero will result in the minimum mix time always being used.

- Click the Close button to save changes and return to the main window of Plant Supervisor PSX.

Further reading

“Do Not Stack” configuration in Plant Supervisor PSX

Panel Bulk Product Settings for Liquid Systems

Still Need Help?

Submit an online web ticket or call us at Kahler Automation 507-235-6648 Option 2.